Gravity Separator

The gravity-based classification of seeds and grains into heavies, mediums, and lights by these machines ensures that the best quality seeds are made available for processing.

Colorsorter

The solutions offered utilize high-resolution cameras to detect either light or dark defects, including either detection of color defects in your products or removing foreign materials. This helps to achieve a consistent quality of grains/seeds. It is particularly utilized in coffee processing plants.

The aim of the process is to decrease the moisture content of solid material or harvested seeds to achieve the following outcomes:

- Eliminate the potential for mold and aflatoxin infections on seeds.

- Improve the shelf life.

- Easy packaging and transportation.

Proper storage of grains preserves the shelf life & reduce insect infestation of the crop produce.

Choosing storage mechanisms requires consideration of:

- Quantity of produce to be stored

- Duration of storage

- Availability of construction materials

- Construction cost

Steel silos

We offer round silos of galvanized and corrugated steel sheets execution with exterior galvanized stiffeners and accessories such as roof ladder, roof inspection door or galvanized catwalks on top of the silo if need be. Our silos range from diameter 6 – 20m and overall volume range between 180 – 4,000 m3

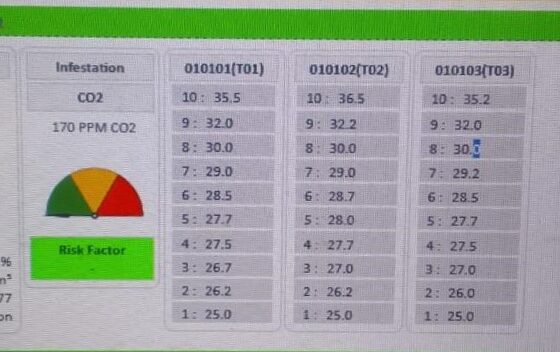

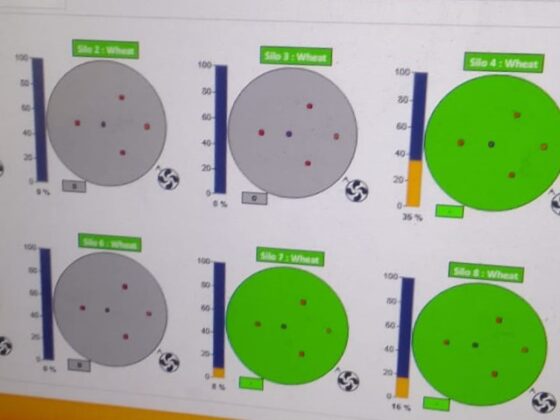

The grain management system entails monitoring & evaluation of stored grain conditions in the silo. Its reporting & management system offers complete solutions for:

- Temperature monitoring via durable digital temperature sensor cables

- Moisture content monitoring using digital moisture sensing cables

- Spoilage detection via CO2 monitoring by the grain sniffer

- Grain level measurement

- Aeration control

- Dashboard Manager which comprehensively stores and monitors the above deduced data

Moisture analyzers

FarmPoint Moisture Analyzer

This analyzer comes with a handle that compresses the grain until it is compact. Additionally, it utilizes high-frequency measurement that enables the analysis to run smoothly and obtain the average of the sample.

FarmPro Moisture Analyzer

The FarmPro grinds grains to a powder-like consistency to ensure that the analysis runs smoothly and produces the most accurate results. It is utilized in various situations, such as measuring the moisture content of grain and seed in the field, during the drying process, and in storag

We offer top-of-the-line coffee milling equipment and unparalleled expertise, ensuring optimal results and customer satisfaction.

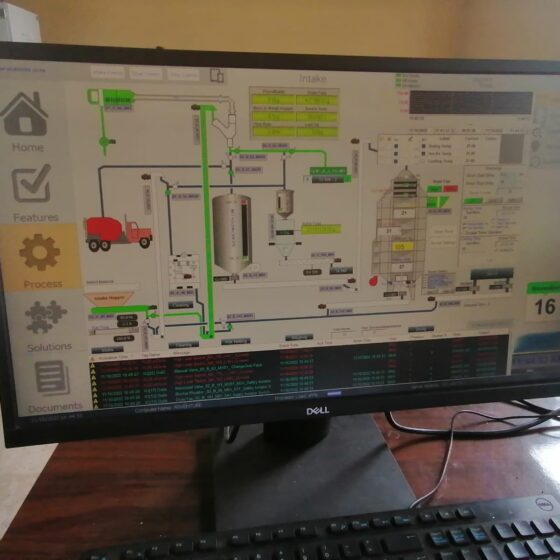

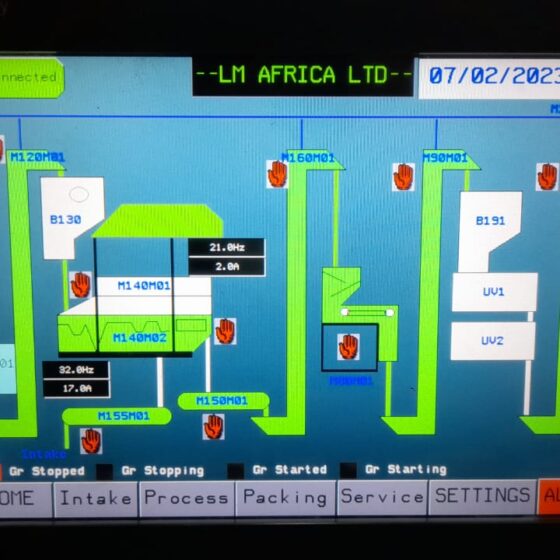

Our company provides a diverse range of coffee milling solutions designed to meet the specific requirements for intake, cleaning, mechanical drying, gravity separation, hulling, polishing, color sorting, roasting for flavour enhancement and packaging of coffee beans.

Colorsorter

The solutions offered utilize high-resolution cameras to detect either light or dark defects, including either detection of color defects in your products or removing foreign materials. This helps to achieve a consistent quality of grains/seeds. It is particularly utilized in coffee processing plants.

Grain and seed processing produces an enormous amount of dust therefore, our dust filters come with flexible suction pipes that filter out contaminated air through filter bags, which trap the dust, releasing clean air to the atmosphere.

Our top-of-the-line aspiration systems considerably reduce machine blockages and atmospheric contamination due to continuous suction and the discharge of dust particles.

We provide seamless conveying solutions to aid in grain transportation. Our expertise lies in installation and maintenance of technologically advanced conveyor systems that optimize efficiency and productivity i.e. screw augers, bucket elevators, chain, belt conveyors.

We offer efficient and safe Plant relocation services of industrial facilities, machinery, and equipment from one location to another.

Our expertise ensures a seamless transition, minimizing downtime and maximizing operational efficiency. With a focus on precision, safety, and cost-effectiveness, we handle the entire relocation process, from planning and disassembly to transportation, reassembly, and testing.

Grain weighing solutions are essential for accurate measurement and management of grain quantities in agricultural and industrial industries.

We offer cutting-edge, reliable, and efficient grain weighing solutions tailored to specific requirements. Our advanced weighing systems ensure precise measurements, enabling clients to optimize inventory management, enhance operational efficiency, and comply with industry standards and regulations.

We prioritize customer satisfaction by providing top-quality products, exceptional technical support, and personalized services. By partnering with us, clients can benefit from our expertise, innovative technology, and commitment to delivering accurate and dependable grain weighing solutions, ultimately improving their productivity and profitability.